Case Studies

View our clients and work.

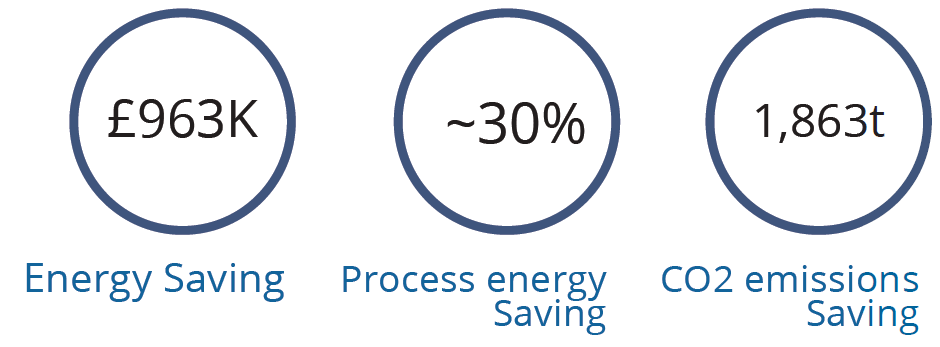

Calbee

2-Day Energy & Net Zero Survey

Problem

Calbee is highly reliant on Natural Gas for a key section of their manufacturing process, using gas fired thermal oil heating for their main frying requirements. To reach Net Zero, Calbee must eliminate their reliance on natural gas whilst not compromising their manufacturing process - ensuring the same high quality of product.

Solution

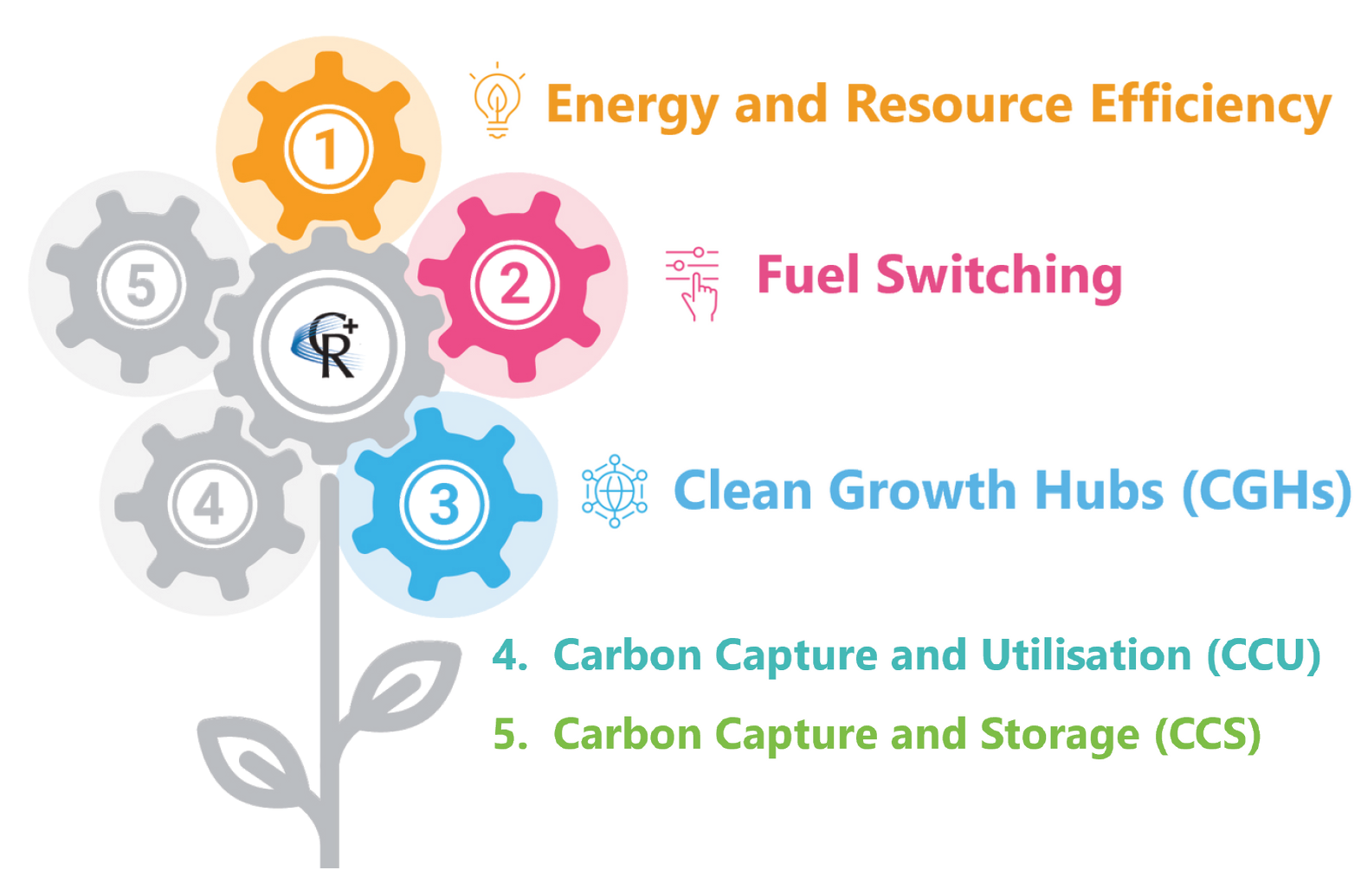

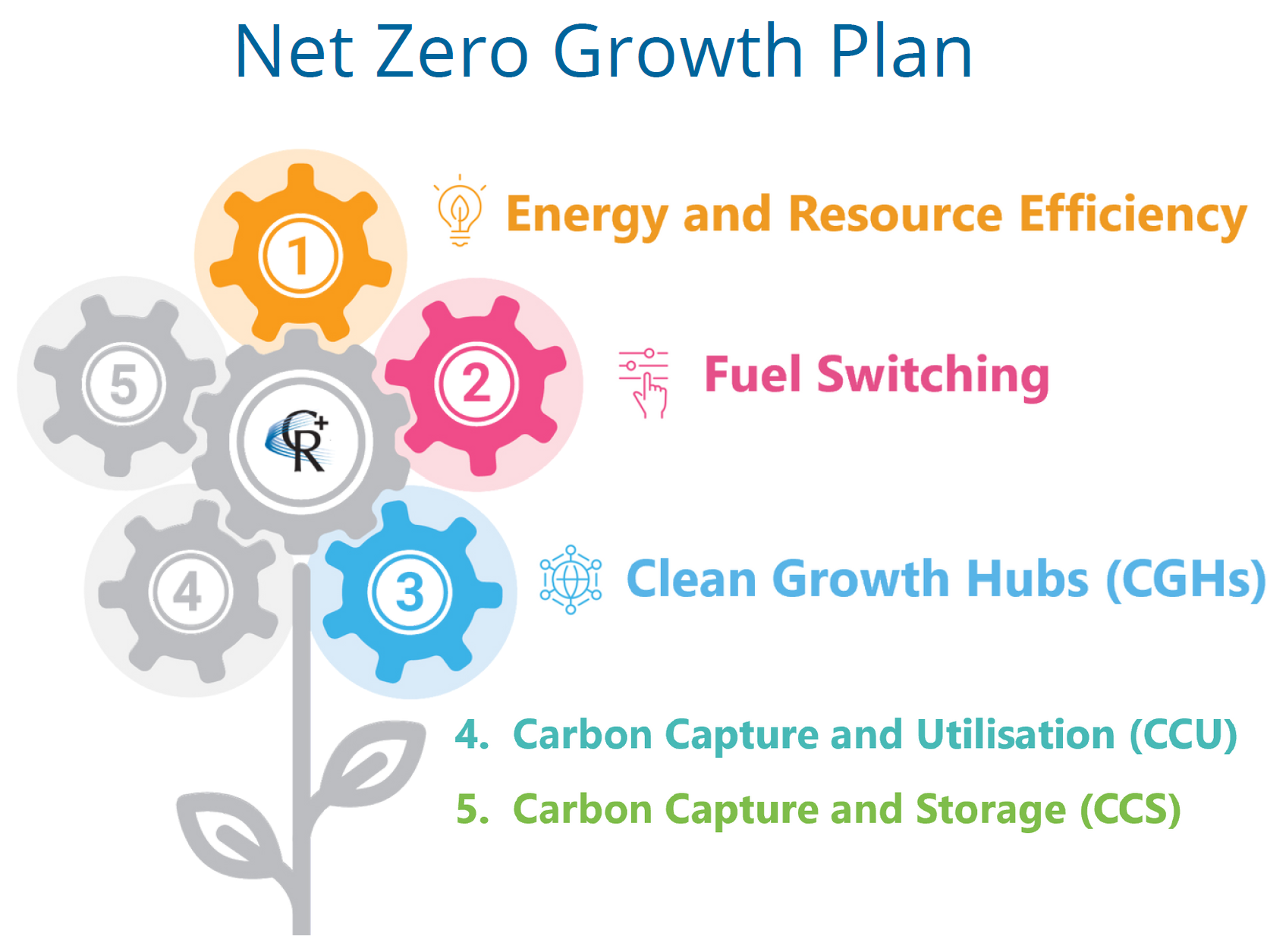

We used our 2-day survey approach to target opportunities for Calbee in our ‘Cogs’ categories of 1) Energy and Resource Efficiency 2) Fuel Switching with a goal of supporting Calbee in achieving 100% switch away from Natural Gas and 3) Clean Growth Hub (to be explored further throughout Bradford Manufacturing Futures LIDP).

The audit highlighted several ways in which expensive energy could be saved or recovered. These included recovering valuable waste heat from the thermal oil stack, fryer exhausts and valorising it to offset gas demand. Calbee also have opportunity to produce their own clean energy through the installation of an Anaerobic Digestion plant to treat waste water currently treated off-site - some of the biogas produced could displace natural gas usage; and solar energy - both ground and roof mounted. The electricity produced could displace some grid reliance. All options will aid in Calbee decarbonisation goals.

CR Plus Services

- Identifying opportunities

- Decarbonisation strategising

- Understanding business strategy to determine appropriate recommendations

- Creating Net Zero pathways linking to business strategies.

Our Client Says

"CR Plus quickly understood and analysed our operations, identifying where energy is consumed throughout our site. They reported on a number of possible energy and carbon saving options, taking into consideration their commercial viability and followed up with further discussions on implementation post the site survey." ~ Group Finance Director

CR Plus in Innovation

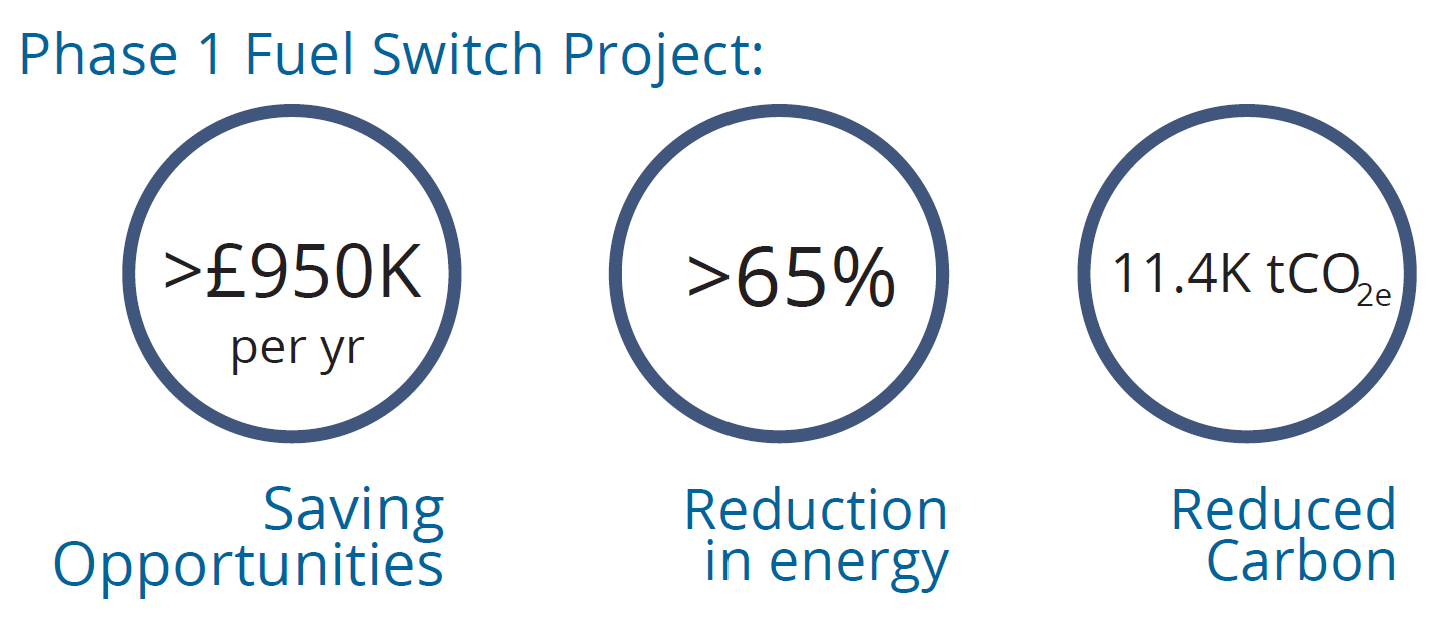

Solenis

3-Day Energy & Net Zero Survey

Goal

Solenis acted as a founding partner of the Bradford Manufacturing Futures Local Industrial Decarbonisation Plan, successfully recruiting multiple other partners to the project which ran through 2024. The Solenis Low Moor facility relies on gas-fired CHP and boilers for power and heat (steam). CR Plus, as the technical partner for BMF, visited in early 2024 to identify, with Solenis, viable decarbonisation pathways to eliminate the natural gas dependence and to link these options to wider infrastructure and neighbour site opportunities.

Solution

Applying its successful ‘Cogs and Roots’approach, CR Plus, via a detailed focus on Cog 2 Fuel Switching during the initial 3-day survey phase, appraised existing opportunities for future Hydrogen and added new concepts into the mix for partial heat electrification. A subsequent phase then investigated further a first step of heat electrification, focused on one particular plant, to form a specific project opportunity. Such heat decarbonisation projects carry higher technical and commercial challenges, therefore CR Plus also identified in Phase 2 options for funding support. Finally, CR Plus took the fuel switching conceptsfurther by linking them to broader Low Moor Clean Growth Hub (Cog 3) spatial opportunities and plans. This activity included facilitating thesharing of ideas and opportunities at a multi site level and pro-active engagement and discussion with regional infrastructure stakeholders, all geared around linking a practical site based project/s to higher level infrastructure plans and ultimately the Bradford industrial cluster plan.

CR Plus Services

- 3-day energy & decarbonisation survey appraising existing ideas, plans, adding alternative approaches and concepts.

- Initial feasibility into heat decarbonisation via a novel electrification approach.

- Funding support opportunities, linked to CapEx cycles.

- Opportunities into Low Moor ‘Clean Growth Hub’as part of the Bradford Manufacturing Futures LIDP (Local Industrial Decarbonisation Plan) Project.

Our Client Says

"CR Plus bring a depth and breadth of experience and knowledge into their work, which has brought insights that we wouldn’t have gained otherwise. They understand the field in great detail and have strong networks, giving us confidence that their proposals reflect the state-of-the-art and are reliable and sound. They are a pleasure to work with." ~ Operational Excellence Manager

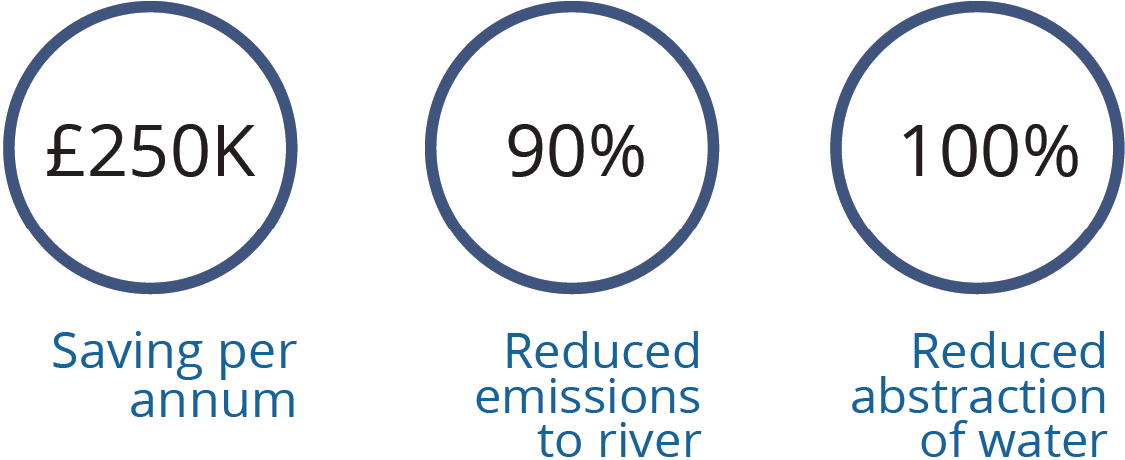

Vale's Clydach Nickel Refinery

Recycled Water Project

Problem

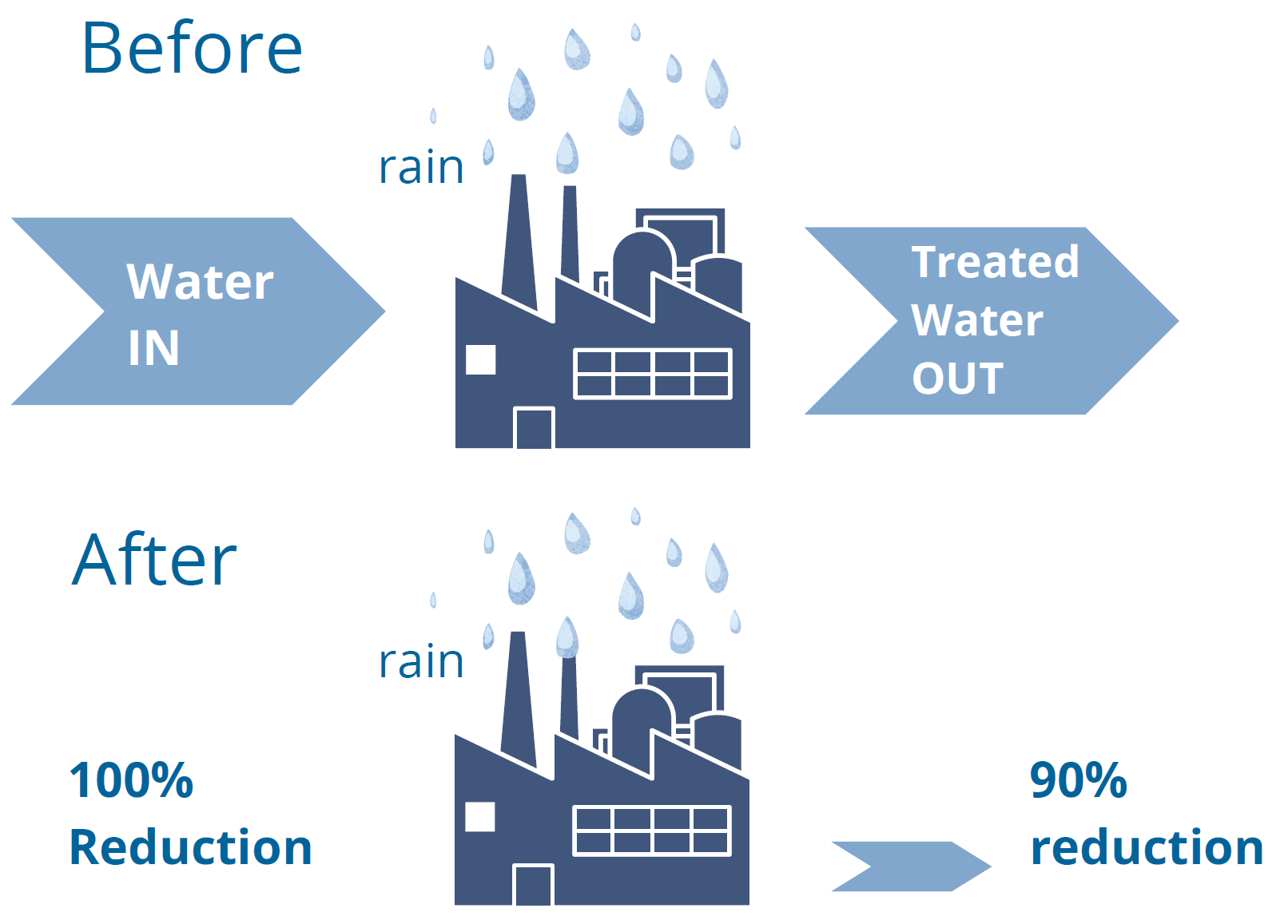

To produce nickel - which is found in everyday items like mobile phones cars and kitchen sinks - the refinery needed to abstract water from the surrounding canal and river for cooling and cleaning processes. They had long wanted to reduce water consumption and were actively looking for a viable solution.

Solution

Direct some of the site effluent treatment plant outflow to a dedicated recycled water circuit for cooling and cleaning purposes. The result: Water abstracted from canal and river is nil and emissions to river were reduced by 90%. The balance is treated before being reintroduced. While reducing the impact on the environment, the project provided stable flows, pressures and temperatures to the site users, while decreasing the load on the effluent treatment plant.

Concept & Feasibility to devise a totally new way of providing cooling water to a complex refinery.

Delivering compliance, process optimisation and energy efficiency during the challenging COVID times, with Vale being a key site.

CR Plus Services

• Feasibility & Outline Design -

measurements, data logging

• PFDs & P&IDs

• Specifications, Schedule & Budgets

• HazOps levels 2, 3, 4 & 5

• Supported Procurement (technical)

• Review detailed designs

• Regular review of contractors’ work

• Commissioning Management

• Regular updating to stakeholders

• Specific solution designs and drawings.

Our Client Says

"We have worked with the CR Plus team for the past 6 years on an innovative recycled water project. The project has also helped us achieve significant process improvements in terms of efficiency and plant availability. CR Plus are well versed in all aspects of the project journey and assisted us in securing government funding before working with us through the FEL stages and onto commissioning and performance monitoring. The team are particularly adept at building a strong level of trust with clients, suppliers and government and adopting smarter, sustainable, low energy solutions to address the challenges of the future." ~ Project Manager at Vale