01639 505050

info@crplus.co.uk

Tata Steel Tafarnaubach

Reducing Energy Usage

< Back to Case Studies

Project Overview

Overall improvements delivered from 2008 to 2011 amount to:

- Electricity - 4 GWh - 33%

- Natural Gas - 18.4 GWh - 35%

~5,200 tCO2e/yr Carbon savings and >£835K/yr overall cost savings (direct energy cost and utilisation improvement)

Summary of Improvements

Engagement with the Tafarnaubach site began in 2008 when the site was Corus owned prior to purchase by Tata. The site’s main manufacturing operation was painting and heat treatment of steel coil strip utilising mains gas for oven burners, Regenerative Thermal Oxidiser (RTO) burner and steam generation for hot strip pre-treatment.

Initial efforts focussed on the process heating loads where two projects were implemented:

- Process Control - Main line turndown and speed control (Phase 1); plant utilisation was below 30% incurring high fixed losses (exhaust and structural heat loss, fan power) during idling.

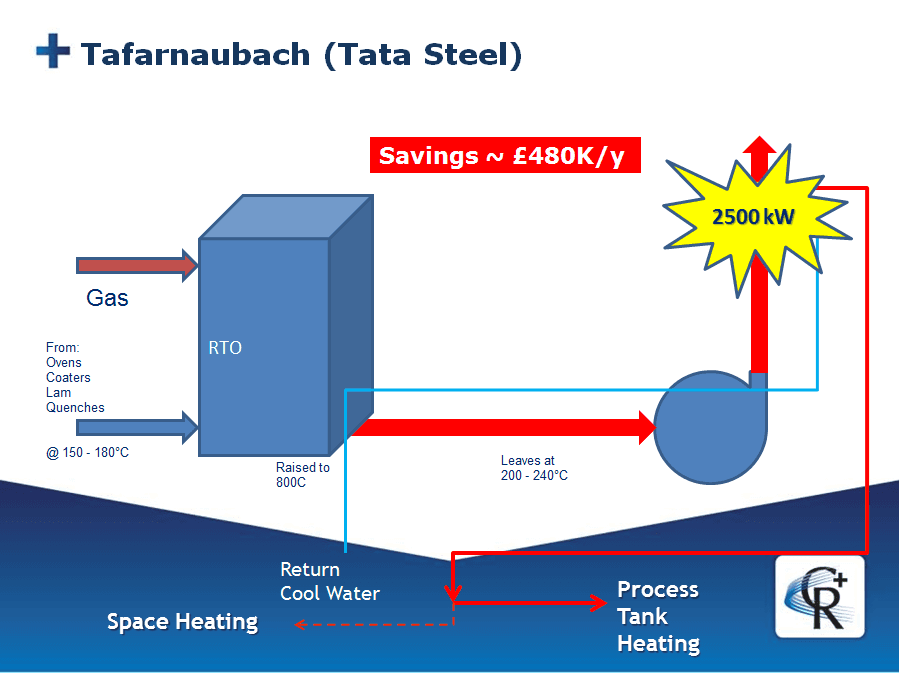

- Energy Recovery - Waste Heat Recovery (Phase 2); installation of an air-water heat exchanger at the exit of the (RTO) to supply heat in the form of pressurised hot water for replacing steam heated process tanks and gas heated space heating.

CR Plus provided end to end support beginning with identifying the savings potential through to undertaking an EPCM role (Engineering, Procurement and Construction Management). Involvement required concept development, specification development, and assistance in procurement, project management & optimisation to project close-out. CR Plus were main project managers working with Corus procurement to fully specify, design, HazOp, control, install and commissioning and ongoing optimisation of the 2 projects.